Granulation Machine Sieves

- Home

- Granulation Machine Sieves

Cad Mill Sieves

Application

- Cad Mill Sieves Are Useful In Granulation Procedures.

- Cad Mill Has Application In Pharma, Food, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergents And Electrolux Industries Etc.

- Cad Mill Design Calibrated And Certified As Per International Standards.

- Cad Mill Available In Various Sizes.

Technical Specifications

Application

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Material Of Construction : Stainless Steel 316-L

- Perforation Sizes Available From 0.5 mm To 15 mm

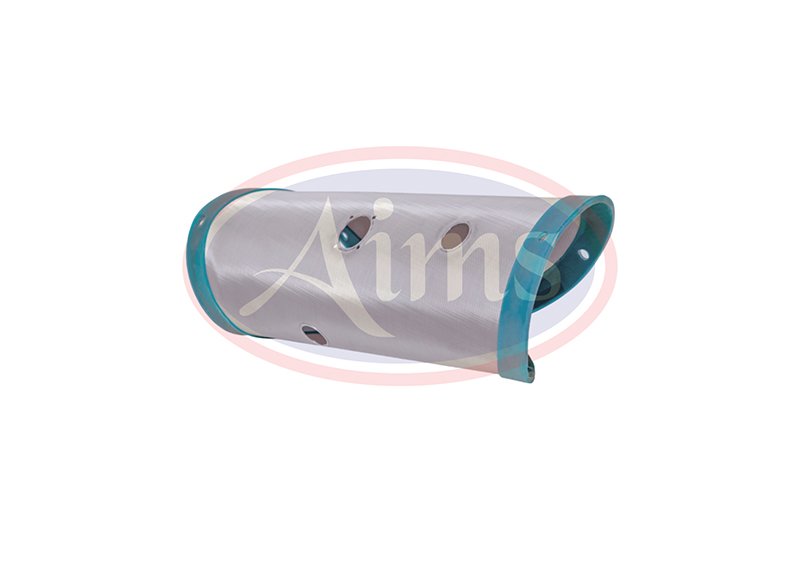

Communiting Mill Sieves

Application

- Communiting Mill Sieves Are Useful In Granulation Procedures.

- Communiting Mill Sieves Has Application In Pharma, Food, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergents, Electrolux Industries Etc.

- Communiting Mill Sieves Design Calibrated And Certified As Per International Standards.

- Communiting Mill Sieves Available In Various Sizes.

Application

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Material Of Construction : Stainless Steel 316-L

- Perforation Size Available From 0.5 mm To 15 mm

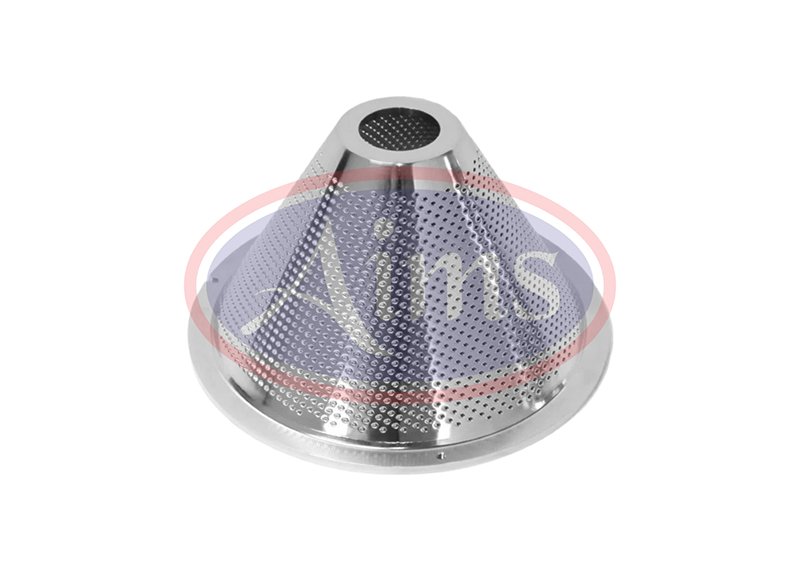

Conical Mills Sieves

Overview

- Conical Mills Used For Liquid / Solid / Gas Filtration With Application In Separation Within The Water, Chemical, Algae, Petrochemical, Oil, Gas, Pharmaceutical, Food, And A Wide Range Of Other Process Industries.

- Milling Is A Particle Size Reduction Process Is Used To Increase Surface Area, Product Uniformity And Improve Formulation Dissolution Properties.

- It Is Also Used To Maintain A Consistent Average Particle Size Distribution (PSD) For The Formulation, Thus Allowing For A Better Quality Mixtures.

- Impact Milling Can Be Used To Generate Particle Sizes Ranging From 850 Microns To 90 microns.

Application

- Conical Mills Sieves Are Useful In Granulation Procedures.

- Conical Mills Sieves Has Application In Pharma, Food, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergents, Electrolux Industries Etc.

- Conical Mills Sieves Design Calibrated And Certified As Per International Standards.

- Conical Mills Sieves Available In Various Sizes.

Technical Specifications

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Material Of Construction : Stainless Steel 316-L

- Perforation Sizes Available From 0.5 mm To 25 mm

Fluid Bed Dryer (FBD) Sieves

Fluid Bed Processor (FBP) Sieves

Fluid Bed Coater (FBC) Sieves

Overview

- Drying Is A Process Of Removal Of Water Or Another Solvent By Evaporation From A Solid, Semi-Solid Mixture.

- Our Sieves Are Free From Toxic Lead & Tin Metals. The Edge Of The Wire Mesh Is Moulded In Silicone / Static Dissipative Rubber Toxicology Tested Polymer.

- The Super Taut Sieve Gives A Better Throughput, Longer Life & Maintains Uniform Aperture Size.

Application

- FBD FBP FBC Sieves Are Useful In Dry Granulation, Wet Granulation, Screening, Crushing, Breaking

- FBD FBP FBC Sieves Has Application In Pharma, Food, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergents, Electrolux Industries Etc.

- FBD FBP FBC Sieves Design Calibrated And Certified As Per International Standards.

- Finer Opening For Better Filtration Efficiency And Quality.

- Handling For Very Hard Material, Sticky Material & High Loads.

Technical Specifications

- Aperture Shape : Dutch Woven

- Aperture Size Available From 20 Microns To 125 Microns

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Molding From Silicone / Static Dissipative

- Material Of Construction : Stainless Steel 316-L Quality

- Available In Size Range : 30 Kg To 500 Kg Capacity

- Available In Silicone / Static Dissipative Rubber Molding, SS Cladding And In Circle Cutting.

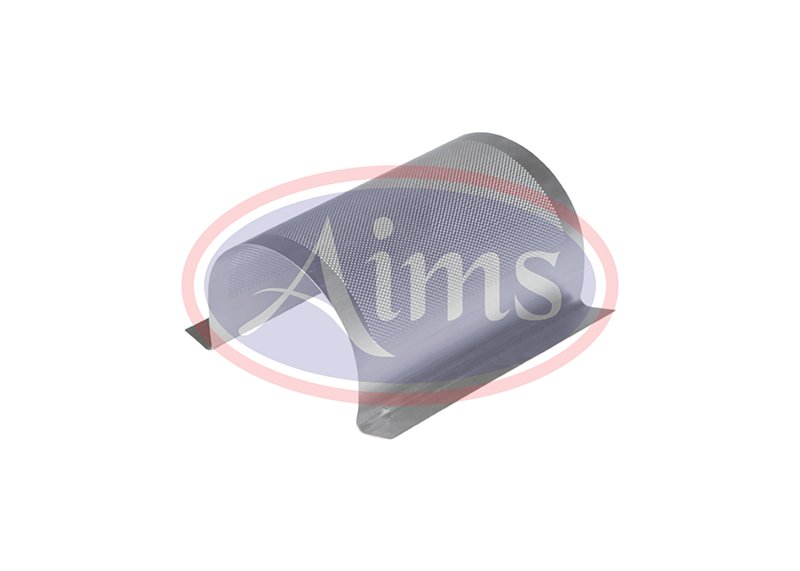

Multi Mill Sieves

Application

- Multi Mill Sieves Are Use In The Process Of Granulation Of Tablets.

- Multi Mill Sieves Are Available In Various Sizes Including Lab Model.

- Multi Mill Sieves Are Available With Complete Set Of Certificates And Standards.

- Multi Mill Sieves Build Procedures Include Special Care Where Perforations Are Specially Designed To Reduce The Possibility Of Accumulation Of Powder And The Joints Are Welded With Argon To Give A Longer Screen Life.

Salient Features

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Import Substitute Designs Available

- Material Of Construction : Stainless Steel 316-L

Technical Specifications

- Perforation Sieves Available In Round, Square Shape

- Perforation Sieves Sizes Available From 0.5 mm To 25 mm

- Multi Mill Screens Outer Diameter 175 mm, 263 mm, 300 mm

- Multi Mill Screens Inner Diameter (Hole) Available In 0.5, 1.0, 1.5, 2, 3, 4, 5, 6, 7, 8, 10, 15, 20, 25 mm

- Multi Mill Wire Mesh Sieves Available In # 4, 6, 8, 10, 12, 14, 16, 20, 24, 30, 40, 50, 40, 50, 60 mm

Oscillating Granulator Sieves

Overview

- Oscillating Granulator Is Important Part In The Granulation Process In Tablet Making Process Which Tablet Is Determined By The Virtue Of The Granules Used For Its Tablet Compression.

- Granulation Is A Mechanical Process In Which The Product Is Pressed Through A Sieve With A Specially Shaped Rotor-Arm To Obtain A Desired Particle Size. Oscillating Granulator Can Be Used For Wet And Dry Aspect Of The Granulation Process.

- Quality Of Granules Are Better Compared To Other Processing Machineries Like Multi Mill, Comminuting Mill Etc. For Proper Granulation Parameters Like Sieve Thick

Application

- Oscillating Granulator Sieves Are Useful In Dry Granulation, Wet Granulation, Screening, Crushing, Breaking

- Oscillating Granulator Sieves Has Application In Pharma, Food, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergents, Electrolux Industries Etc.

- Oscillating Granulator Sieves Design Calibrated And Certified As Per International Standards.

- Oscillating Granulator Sieves Available In Various Sizes.

Technical Specifications

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standard

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Material Of Construction : Stainless Steel 316-L

- Perforation Sizes Available From 0.5 mm To 15 mm

Vibro Sifter Sieves

Application

- Vibro Sifters Usually Use For Vibration Energy Or A Combination Of Vibration & Ultrasonic Energies To Achieve Screening.

- Vibro Sifter Sieves Are Specially Designed To Resist The High Tensile Stress Generated.

- Since Particle Size Distribution Plays A Vital Part In Drug Dissolution, Maintaining The Accuracy Of The Sieve Apertures Is An Essential Part Of Sieve Manufacturing.

- Proper Thickness Of Wire, Accurate Nominal Aperture Sizes, High Tensile Strength & Tautness Of The Sieve Are Essential For High Sifting Performance.

Salient Features

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Import Substitute Designs Available

- Material Of Construction : Stainless Steel 316-L

- Moulded From Lead Free Transparent Silicon & Static Discharge

- Sieves Dimensions Available From 150 mm To 120 mm

- Sieves Sizes Available From Diameter 40 mm To 1220 mm

- Sieves Mesh Sizes Available From 4 # ASTM To 400 # ASTM