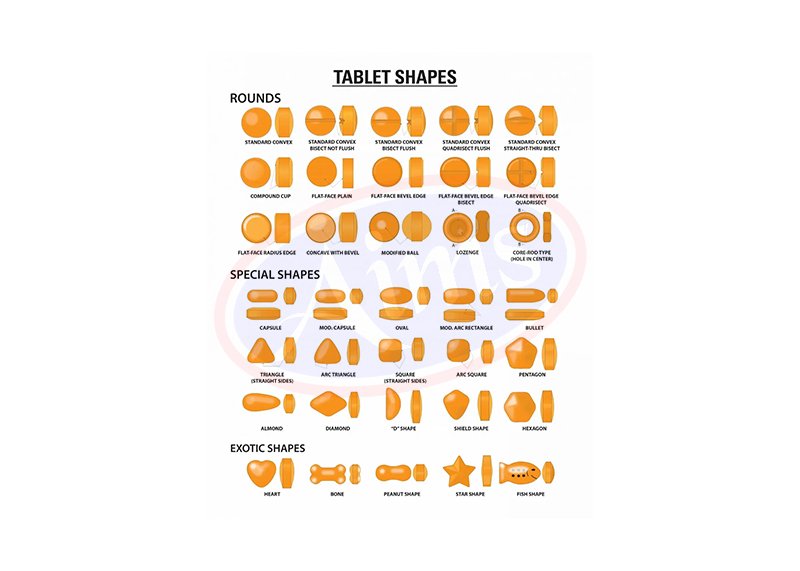

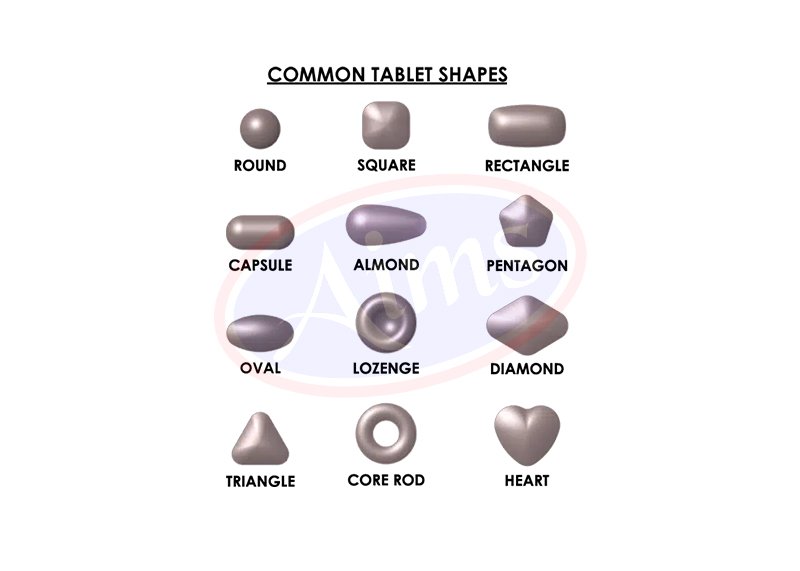

AIMS Manufactures & Exports The All Types Of Tablet Compression Tooling - Punches & Dies In Pharmaceuticals, Ayurvedic, Nutraceuticals & Many More Industries Applications Worldwide.

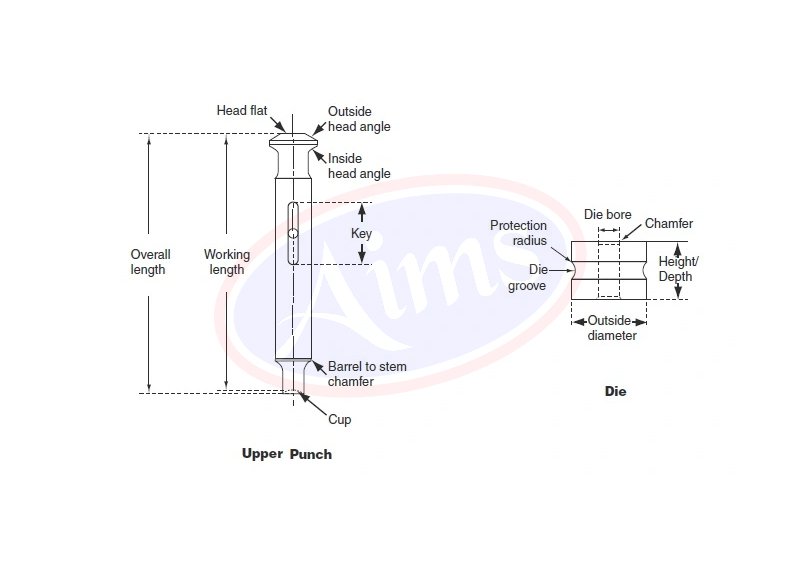

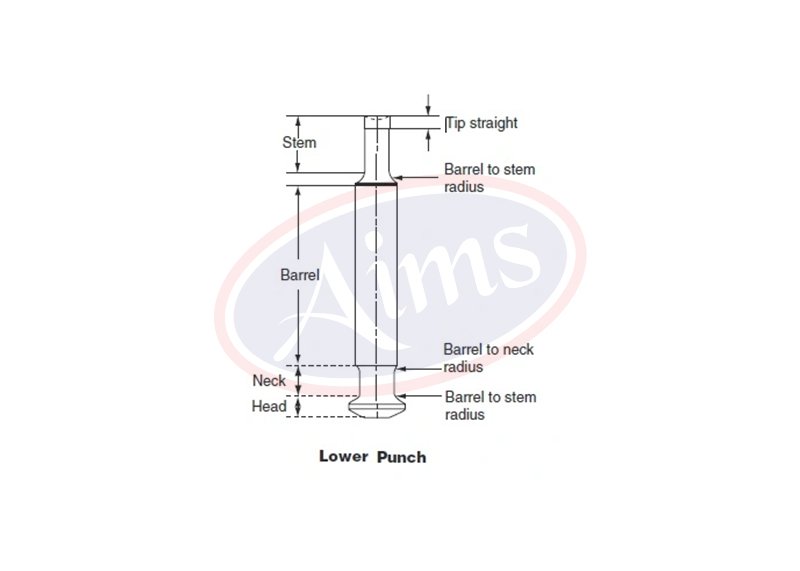

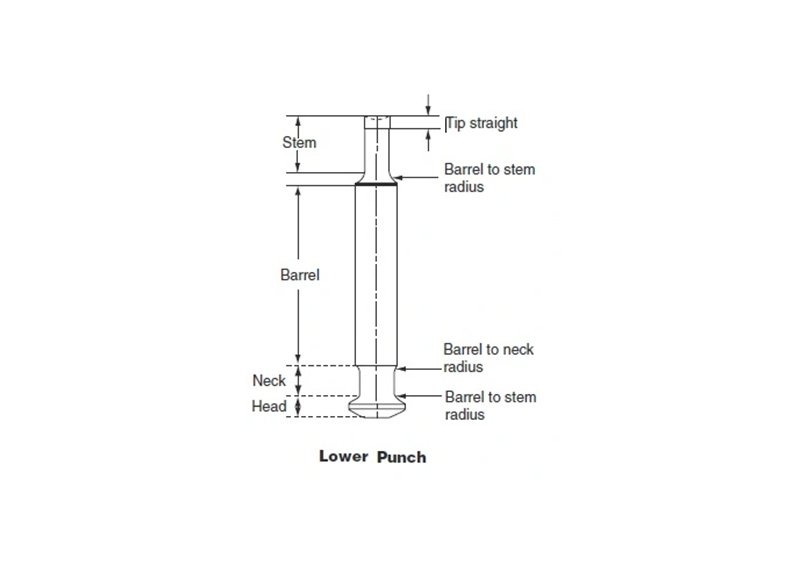

• Punches & Dies Are The Most Vital Change-Parts Of The Tableting Process. They Are Responsible For The Final Appearance And Shape Of The Manufacturing Tablets. AIMS Supplies Tablet Punches And Dies And All Types Of Tablet Press Tooling Installed In Pharmaceuticals, Ayurvedics, Nutraceuticals & Many More Applications Worldwide.

Aims Pharma Machineries Maintains The Largest Inventory Range Of Tablet Compression Machine Replacement Spare Parts In Ready Stock For Immediate Delivery To Worldwide.

AIMS Has Built A STATE-OF-ART Plant With In-House CAD-CAM Supported CNC Machines With The Latest Manufacturing Techniques Available Around The World For Manufacturing Tablet Compression Tooling - Punches & Dies.